DTF Transfers Printer revolutionizes custom apparel printing with intricate, vibrant designs via heat and pressure. Ideal for on-demand production, it offers faster times and high-quality details compared to traditional methods. Selecting the right printer involves considering advanced features like high-res printing, versatile color support, larger print beds, and extensive color gamuts. Mastering print settings ensures superior results, preventing issues like ink skipping. Pre-heating and using quality DTF transfers enhance overall printing experience, delivering crisp, vibrant designs on various fabrics.

“Unleash your creativity with DTF (Direct-to-Film) transfers, a game-changer in printing complex designs. This guide navigates the process of creating intricate patterns with a DTF transfers printer. We’ll explore the benefits of this technology and help you choose the ideal machine for your needs. From mastering print settings to understanding techniques, gain insights on achieving exceptional quality results. Discover how to transform your ideas into vibrant, detailed designs ready for application.”

- Understanding DTF Transfers and Their Advantages

- Choosing the Right DTF Printer for Complex Designs

- Mastering Print Settings and Techniques for Quality Results

Understanding DTF Transfers and Their Advantages

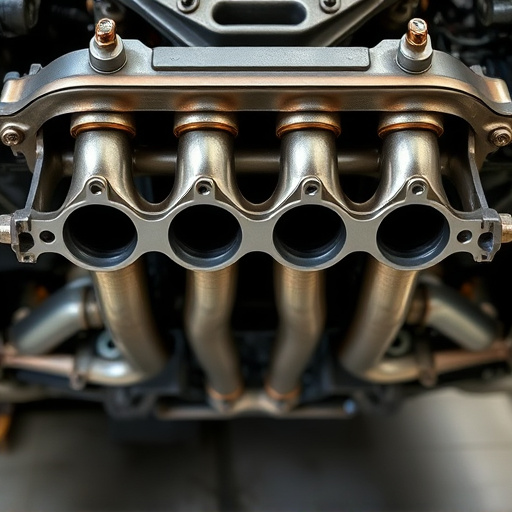

DTF (Direct to Fabric) transfers are a cutting-edge printing technology that has revolutionized the way we create custom designs on various materials, particularly in the apparel industry. This method involves transferring ink directly onto fabric using heat and pressure, enabling intricate and vibrant designs to be achieved with ease. With a DTF Transfers Printer, artists and businesses can produce high-quality, detailed prints on demand, making it an attractive option for those seeking unique and personalized products.

One of the key advantages of DTF printing is its versatility. It allows for complex designs with fine lines, gradients, and full-color imagery to be reproduced accurately on a range of fabrics. This technology is especially popular for creating custom hoodies, t-shirts, and other clothing items, as it ensures the design’s integrity and longevity. Additionally, DTF transfers offer faster production times compared to traditional printing methods, making them ideal for businesses that need to fulfill orders promptly while maintaining excellent print quality.

Choosing the Right DTF Printer for Complex Designs

When venturing into the realm of printing complex designs with a DTF (Direct to Garment) transfers printer, selecting the appropriate machine is paramount. The right DTF printer should offer intricate details and precision, capable of handling the nuances of your desired design—be it subtle lines or bold graphics. Look for features such as high-resolution printing, advanced color profiles, and support for various file formats, ensuring you can effortlessly transfer your digital creations onto fabric.

For complex designs, consider printers with robust hardware and software capabilities. These might include larger print bed sizes to accommodate bigger projects and more extensive color gamuts, enabling you to produce vibrant, detailed transfers suitable even for logos and intricate patterns of clothing brands. Remember, the right DTF printer will not only streamline your design process but also elevate the final product’s quality.

Mastering Print Settings and Techniques for Quality Results

Mastering print settings and techniques is key to achieving high-quality results with a DTF Transfers Printer. Begin by understanding your specific printer model’s capabilities and limitations, as settings may vary between manufacturers. Typically, this involves adjusting resolution, color profiles, and printing mode for optimal outcome. Higher resolutions ensure finer details in complex designs, making them ideal for intricate patterns or text. Color management is crucial when dealing with dtf transfer sheets; ensuring accurate color representation on the final product, whether it’s for custom apparel like hoodies or other fabric items.

Experimenting with different printing techniques can also elevate your results. Consider using test prints to identify potential issues like ink skipping or smudging, which may occur during complex print jobs. Techniques such as optimizing image scaling and adjusting ink levels can prevent these problems. Additionally, pre-heating the printer and using high-quality dtf transfers can significantly improve the overall printing experience, ensuring your designs are crisp, vibrant, and free from imperfections when applied to various materials.

Printing complex designs with a DTF (Direct to Fabric) transfers printer offers endless creative possibilities. By understanding the advantages of DTF technology, selecting the appropriate equipment, and mastering print settings, you can achieve exceptional quality results for your fabric projects. Whether you’re an experienced designer or just starting, harnessing the power of a DTF Transfers Printer opens up a world of vibrant, detailed designs ready to transform various materials.